Ancient Roman pozzolanic concrete is still standing strong after two thousand years, and not only does it resist damage, but salt water actually makes it stronger. Researchers have been studying samples of the concrete and found that volcanic ash, lime and seawater are the main ingredients. Even better, but its real strength comes when those ingredients interact with the seawater pounding on the surface.

Ancient Roman pozzolanic concrete is still standing strong after two thousand years, and not only does it resist damage, but salt water actually makes it stronger. Researchers have been studying samples of the concrete and found that volcanic ash, lime and seawater are the main ingredients. Even better, but its real strength comes when those ingredients interact with the seawater pounding on the surface.

What if there was a type of concrete that gets tougher the older it gets, and by being in seawater? What if instead of needing repairs or replacement after a few decades, it could still be standing after more than a thousand years?

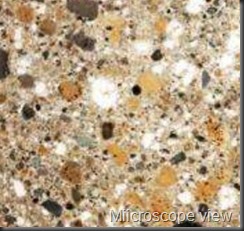

Roman marine concrete structures, composed of a volcanic ash (a ‘pozzolan’[1]) and hydrated lime mortar that binds conglomeratic tuff (a kind of volcanic ash ‘rocky road’) or carbonate rock aggregate (coral or limestone rubble), have remained intact and coherent for 2000 years, either fully immersed in seawater or partially immersed in shoreline environments. The combination of ash, water, and quicklime produces what is called a pozzolanic reaction. For underwater structures, lime and volcanic ash were mixed to form mortar, and this mortar and volcanic tuff were packed into wooden forms. The seawater instantly triggered a hot chemical reaction. The lime was hydrated, incorporating water molecules into its structure, and reacted with the ash to cement the whole mixture together.

Modern Portland cement concrete also uses rock aggregate, but with an important difference: the sand and gravel particles are intended to be inert. Any reaction with the cement paste could form gels that expand and crack the concrete.

Modern Portland cement concrete also uses rock aggregate, but with an important difference: the sand and gravel particles are intended to be inert. Any reaction with the cement paste could form gels that expand and crack the concrete.

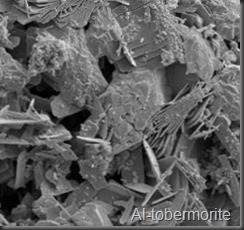

Researchers from Berkeley Lab and the University of Utah studied samples of ancient concrete from 2,000-year-old harbor structures in Orbetello, Italy, and found that when seawater seeps into the concrete, it dissolves the lime inside. Instead of corroding it, as for modern concrete, it strengthens the ancient concrete. The highly alkaline leached fluids produced by dissolving the lime allow the growth of interlocking crystals of Al-tobermorite and phillipsite, plugging the holes, preventing cracks and increasing its strength because they grow in flat shapes that interlock. The ancient concrete thrives in open chemical exchange with seawater.

Portland cement is the source of the “glue” that holds most modern structures together and we use 19 billion tonnes of it per year. Making it releases carbon from burning fuel, needed to heat a mix of limestone and clays to 1,450 degrees Celsius and from the heated limestone (calcium carbonate) itself. Romans used much less lime and made it from limestone baked at just 900˚C or lower, requiring far less fuel than Portland cement. Cutting emissions and fuel use would be reason enough to find a better way to produce concrete. In the middle 20th century, concrete structures were designed to last 50 years, but now we design buildings to last 100 to 120 years. Yet Roman harbor installations have survived 2,000 years of chemical attack and wave action underwater.

The conglomerate-like Roman concrete was used in many architectural structures, including the Pantheon and Trajan’s Markets in Rome. Reviving this ingenious technique would be handy today, especially for islands, but the exact formula is still unknown. The researchers are experimenting with different combinations of seawater and volcanic rock to try to unlock its secrets, with a view to building longer lasting seawalls, dams and piers.

The conglomerate-like Roman concrete was used in many architectural structures, including the Pantheon and Trajan’s Markets in Rome. Reviving this ingenious technique would be handy today, especially for islands, but the exact formula is still unknown. The researchers are experimenting with different combinations of seawater and volcanic rock to try to unlock its secrets, with a view to building longer lasting seawalls, dams and piers.

Roman pozzolanic concrete takes time to develop strength from seawater, and features less compressive strength than typical Portland cement. It is, however, important for its practical applications and could replace 40% of the world’s demand for Portland cement. And there are sources of pozzolan all over the world. Stronger, longer-lasting modern concrete, made with less fuel and less release of carbon into the atmosphere, may be the legacy of a deeper understanding of how the Romans made their concrete. Volcanic materials are common on the Pacific’s high islands, but absent from its atolls. Tuvalu, an atoll country, has been importing more and more building raw materials over the past few years (cement, sand, and aggregates), so importing volcanic ash from high islands may not be so out of the question.

Sources:

https://newatlas.com/roman-concrete-stronger-seawater/50343/

Marie D. Jackson, et al. 2017 Phillipsite and Al-tobermorite mineral cements produced through low-temperature water-rock reactions in Roman marine concrete. American Mineralogist (2017) 102 (7): 1435-1450.

https://phys.org/news/2013-06-roman-seawater-concrete-secret-carbon.html

http://ferrocement.net/ferro/files/pozzolans-uwe.html

https://www.extremetech.com/wp-content/uploads/2017/07/Al-Tobermorite-Uni.jpg

[1] Pozzolans are mostly volcanic ashes, pumice and tuffs, but may include fly ash (from coal burning) and other organic ashes. They are siliceous or siliceous and aluminous materials, which in themselves possesses little or no cementing property, but will in a finely divided form, and in the presence of moisture, chemically react with calcium hydroxide at ordinary temperatures to form cements.